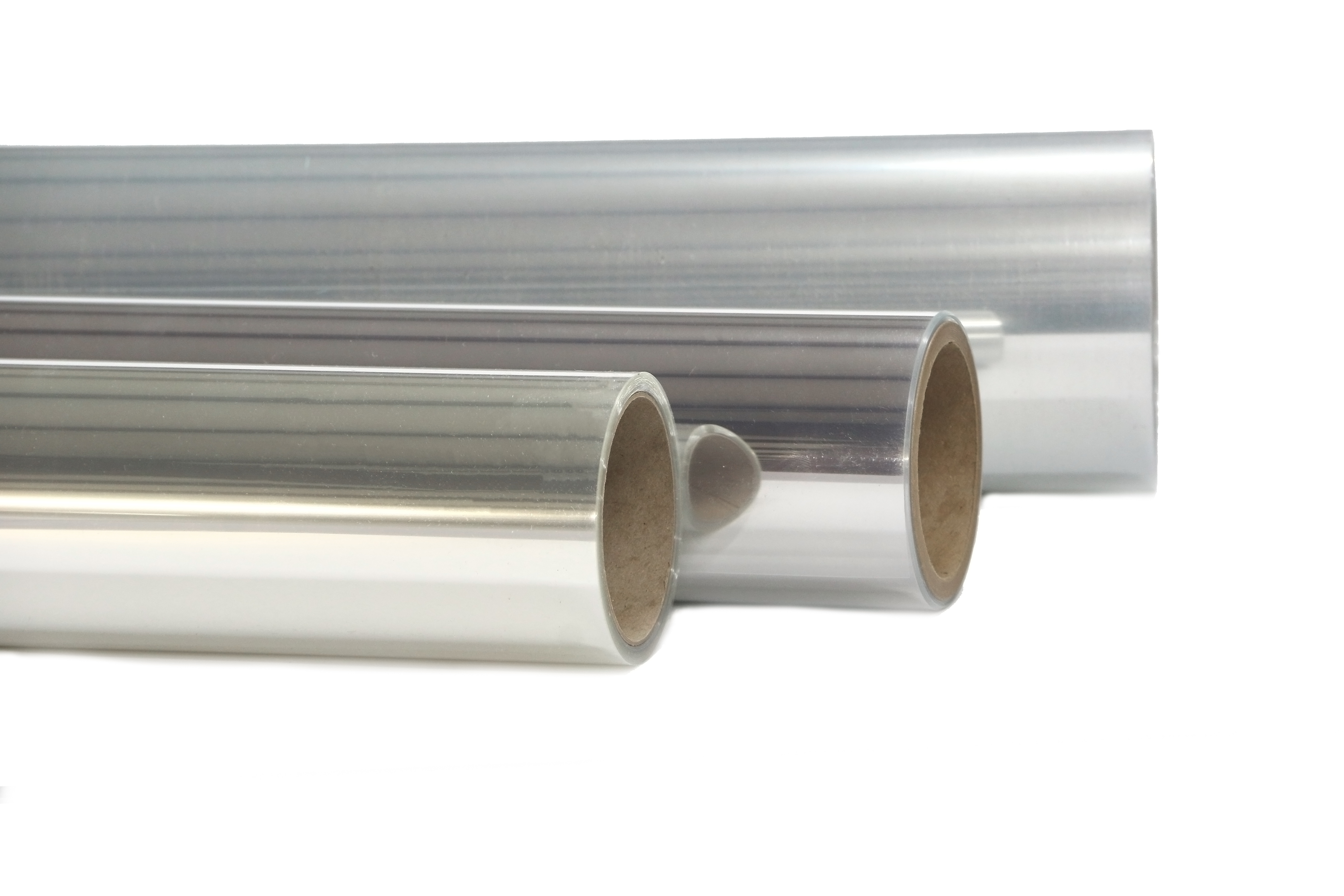

CS Hyde stocks and converts various clear plastic films for face Shield, sneeze guards, or sanitary barrier applications. Our clear plastic films are available in various thicknesses and types including Polyester (PET), Polycarbonate (PC), and Polyethylene Terephthalate Glycol (PETG). These clear films have exceptional clarity and are easy to fabricate. Polyester film is more chemical resistant, Polycarbonate is more abrasion resistant, PETG Film is the most cost effective. These clear films are currently being used to fabricate alternative disposable face shields, sneeze guards, or sanitary barrier applications.

CS Hyde stocks and converts various clear plastic films for face Shield, sneeze guards, or sanitary barrier applications. Our clear plastic films are available in various thicknesses and types including Polyester (PET), Polycarbonate (PC), and Polyethylene Terephthalate Glycol (PETG). These clear films have exceptional clarity and are easy to fabricate. Polyester film is more chemical resistant, Polycarbonate is more abrasion resistant, PETG Film is the most cost effective. These clear films are currently being used to fabricate alternative disposable face shields, sneeze guards, or sanitary barrier applications.

As our contribution CS Hyde Company has waived all set up costs and minimums to cut .DXF drawing face shields. Essentially, if you supply a .DXF Drawing of a face shield, select material thickness and type, we will cut the sheets in house utilizing our digital knife cutting capability. This cutting process creates smooth edges and holes and does not discolor clear material or deposit smoke residue like laser cut sheets. Precut sheets can be utilized to speed up installation and eliminate extra labor and cost. This is an ideal option if you are utilizing 3d printing to fabricate the visors or frames that the clear plastic films attach too. Although, If you are making a simple version face shield these clear plastics are easy to cut and can be cut to size with a utility razor. If you are interested in CS Hyde cutting shields, please email drawing and quantity to sales@cshyde.com.

*Please note this category is only a recommendation of products- These plastics have not been FDA cleared or approved.

CS Hyde can not provide a cert. for any intended use. You (the customer) must check with your institution or customer to see if these materials are compliant for intended use

CS Hyde Co. supplies and converts different adhesive tapes, polymer films, fabrics, and silicone sheeting that are FDA approved by the Food and Drug Administration (FDA). What does FDA Approved mean? FDA approved materials meet FDA guidelines for safe, direct, and indirect contact with food. To be FDA compliant these plastics must have performance properties that enable them to withstand their environment, and not undergo physical changes during application use. These performance properties include high temperature resistance, chemical resistance, wear resistance, and water/moisture resistance. These properties are important because just like the materials that are used to preserve food, beverages, and drugs the materials used to manufacture, store, and transport must be FDA compliant as well. These materials are ideal for industries including medical, packaging, and industrial. Application solutions include surface protection, insulation, guide rails, medical device components, conveyor belts, storage bins, or anywhere with direct food contact.

CS Hyde makes its easy to incorporate these FDA approved materials into your application by utilizing on site converting capabilities. We can custom slit material or produce specialty die cut parts designed from .DXF drawings, or sheet materials to custom dimensions. Ultimately, CS Hyde can find a solution that enables your application to incorporate these FDA approved materials and their performance properties.

/Asset/fdaapproved.jpg

CS Hyde supplies low friction PTFE coated, and PTFE formulated tapes ideal for heat seal surfaces on packaging machinery. These selections of PTFE tapes are ideal for heat sealing equipment as release surfaces on sealers, blister formation and form-fill-seal equipment. All these products are stock items, and ship in 1-2 business days. We also can produce custom slit rolls or sheets if a size listed does not meet your requirements.

/Asset/fiberglassvarietry.jpg

Below are common die parts that we stock. This selection of die cuts is ideal for peel and stick applications because they are produced on a removable liner. We specialize in creating custom die cut solutions for almost any application. Our performance material line helps us find a product that will ensure reliability and functionality of your design.

CS Hyde Company offers design assistance, prototype and short production runs, high volume production and inspection or quality control. We can assist with concepts, manufacturing costs and techniques and material recommendations. We can also help with upgrading or redesigning of existing materials and products to increase performance and reduce costs.

Need a different size or custom parts? Request Quote Now

CS Hyde Company has an extensive line of thermal spray and plasma flame spray tapes available. High temperature resistance (up to 550F) makes them ideal for plasma flame spray masking applications. Various Colors. Cut to width. Types include silicone coated fiberglass, foil coated fiberglass, double and triple-ply silicone & fiberglass tapes, and double sided fiberglass tape.

/Asset/Plasma Flame Spary Masking Tape group pt2.jpg